Automatic milking systems (AMS) have perceived labour benefits which are attracting interest within the Northern Irish dairy sector, particularly in light of increasing herd sizes and reductions in the agricultural workforce.

When switching to an automatic milking system in Northern Ireland, one typically also shifts to an all-year-round calving pattern. This results in varied energy requirements within the herd and meeting these varied needs of individual cows through a partial mixed ration (PMR) is often very difficult. Therefore, there is a need to provide those cows with a high energy requirement (usually early lactation and high yielding cows) with supplementary concentrate. Typically, this is done in the milking robot feed station or through out-of-parlour feeders.

Within automatic milking systems, the milking robot feeder seems the natural choice. However, the amount of concentrate a cow is able to consume is limited by her milking frequency, milking time, and eating speed. These can all result in cows simply not having enough time in the milking robot to consume adequate concentrate.

Out-of-parlour feeders have been suggested as a useful source of additional concentrate for AMS. However, as concentrate feed provision within the robot is used to motivate cows to get milked, it is important to understand if feeding additional concentrate with out-of-parlour feeders would have a detrimental impact on robot visit frequency. This study, which was funded by DAERA, DoE and AgriSearch, aimed to address this question.

The study

Forty-eight cows were indoor-housed for the duration of the short study and had free access to a single milking robot and two out-of-parlour feeders. PMR containing grass silage and whole crop (80% and 20% of dry matter, respectively) as well as 2kg concentrate blend per cow was delivered once daily. Cows were allocated to one of two treatments: ‘robot high’ cows received 80% of their additional concentrate ration in the milking robot feeding station, and 20% through out-of-parlour feeders, whereas ‘robot low’ cows received 20% of their additional concentrate in the milking robot feeding station and 80% through out-of-parlour feeders.

Results

Milking robot and out-of-parlour feeder visits

There were no differences between groups in the number of successful milking visits (where the cow was milked) or unsuccessful milking visits (when the cow returns to the robot too soon after her previous visit and isn’t milked). However, visit rate to the out-of-parlour feeders did differ: ‘robot high’ cows visited the out-of-parlour feeders on average 8.01 times fewer per week than ‘robot low’ cows. ‘Robot high’ cows had a particularly low out-of-parlour visit frequency in week 4, with almost half as many visits as ‘robot low’ cows.

Table 1: Number of out-of-parlour feeder visits per group per week of the trial

| Robot High | Robot Low | |

| Out-of-parlour feeder visits week 1 | 24.4 | 32.5 |

| Out-of-parlour feeder visits week 2 | 24.1 | 30.9 |

| Out-of-parlour feeder visits week 3 | 22.3 | 30.6 |

| Out-of-parlour feeder visits week 4 | 16.4 | 30.8 |

Feed intake and milk yield

‘Robot low’ cows consumed more of their allocated daily concentrate ration (combined between milking robot feed station and out-of-parlour feeders), leaving on average 192.5g in comparison to ‘robot high' cows that left an average of 379g. ‘Robot high’ cows consumed an average of 46.3 kg of PMR, whereas ‘robot low’ cows consumed an average of 49.4 kg. However, ‘robot high’ cows consumed less PMR than ‘robot low’ cows during week 1 only, thereafter there were no differences in PMR intake between treatments. There were also no milk yield differences between treatments.

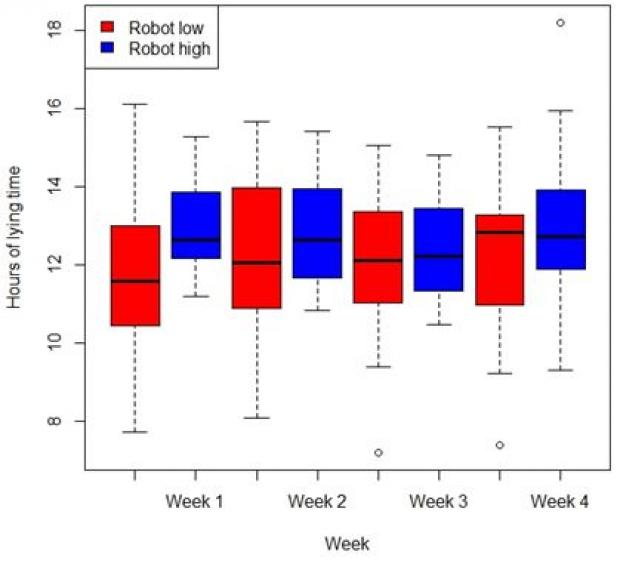

Lying time

No difference between ‘robot high’ and ‘robot low’ cows was found in the number of hours of lying time per day.

Conclusions

Providing cows with most of their concentrate ration outside of the milking robot did not decrease their milking frequency. In line with this, yield was not affected by the location where most concentrate were provided (which would be expected if milking frequency had been lower). Furthermore, cows receiving most of their concentrate within the milking robot did not show a higher numbers of unsuccessful milking visits. Thus, it was not surprising that there was no effect on lying time either (which would have been expected if an increase in unsuccessful milking visits increased queues at the milking robot). Interestingly, cows with a higher allocation within the out-of-parlour feeders visited these more often, meaning that cows can adjust their visits as needed to reach their energy requirements.

Although milk yield was maintained regardless of feed allocation patterns, cows with higher allocations within the milking robot did leave higher amounts of concentrate unconsumed, which is an area of concern. This further confirms that consumption of very high levels of concentrate within the milking robot is limited by the time available during milking. Many cows simply may not have sufficient time during milking to consume their full feed ration.

Regarding PMR intake, cows provided with more concentrate in the milking robot had lower PMR intakes in week 1 than the ones provided with more concentrate in the out-of-parlour feeder, but the effects did not persist past week 1. This short study yielded promising results, as well as several options for future research.

Additional research is recommended on varying herd sizes, management routines, and housing layouts. This study represents a single component of a larger-scale research project on productivity and welfare within robotic milking systems currently underway at AFBI Hillsborough which is, amongst other things, investigating ways to optimise milking visit frequencies and how to manage a robotic milking herd at pasture.

Take home messages

This study has demonstrated that allowing cows within automatic milking systems to access concentrate in locations other than the milking robot feeding station has no adverse effects on robot visits, yields or lying time. However, provision of more feed outside the milking robot reduced the amount of concentrate left uneaten, which would have a beneficial effect on farm efficiency. Farmers should ensure that cows are not over-allocated concentrate feed within the milking robot.

Notes to editors:

AFBI’s Vision is “Scientific excellence delivering impactful and sustainable outcomes for society, economy and the natural environment”.

AFBI’s Purpose is “To deliver trusted, independent research, statutory and surveillance science and expert advice that addresses local and global challenges, informs government policy and industry decision making, and underpins a sustainable agri-food industry and the natural and marine environments”.

AFBI’s core areas:

- Leading improvements in the agri-food industry to enhance its sustainability.

- Protecting animal, plant and human health.

- Enhancing the natural and marine environment.

Latest news

- AFBI makes major announcement on the building of a new research vessel for Northern Ireland 17 April 2024

- AFBI issues Nematodirus Warning – Spring 2024 04 April 2024

- Farming for the Future - Major AFBI Open Days on 18 - 19 June 02 April 2024

- Northern Ireland Science Festival 28 March 2024